How Massive Dimension Used 3D Printing Technology to Create Customized Letters for Louis Vuitton

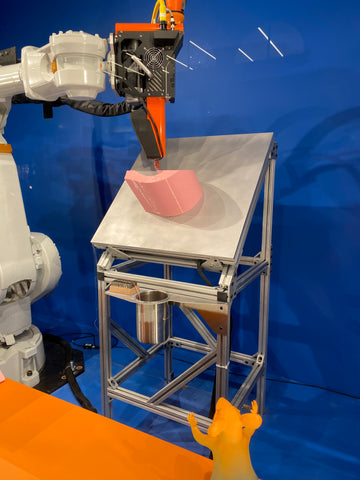

In celebration of the Louis Vuitton 200 Trunks exhibit, Massive Dimension has created a custom 3D printing setup to produce letters. The team used its large format 3D printer equipment and an ABB IRB4400 robot arm to create the customized letters quickly. This was a quick turnaround project, from idea to commissioning in only three weeks!

The Massive Dimension team is known for its innovative use of 3D printing technology. This time, they have outdone themselves with a specialized 3D printing setup that was used to create customized letters for the Louis Vuitton 200 Trunks exhibit.

By leveraging the advantages of robotic printing, a custom-positioned build surface fixture was created for this retail display. This customization was done to solve the client's request, to honor the letters, and respect the brand. This build orientation required no changes to the original CAD models, as all the back surfaces are supported during the build process.

This setup highlights Massive Dimension's expertise in setting up custom printing cells. In a few days, under three weeks, the MD team could develop this new printing method, set up all the equipment, provide user training, and final commissioning.

If you want to see this printer in action stop by 660 Madison Avenue, New York, NY where the Louis Vuitton 200 Trunks exhibit is happening. The printer will be running during store hours and will produce one letter in about 3-4hrs. It’s a great opportunity to see 3D printing in action and the impressive results that can be achieved with this technology. Overall, Massive Dimension's customized 3D printing setup is a perfect example of how this innovative technology can be used to create stunning displays quickly and easily.